The Essential Features of CAD: Revolutionizing Design and Engineering

Computer-Aided Design (CAD) has become an indispensable tool in various industries, from architecture and engineering to manufacturing and graphic design. This article explores the essential features of CAD software that make it a powerful asset for designers and engineers.To get more news about features of cad, you can visit gstarcad.net official website.

1. Modern and Ergonomic User Interface

One of the most critical features of CAD software is its user interface. A modern and ergonomic interface enhances productivity by making the software easy to use. Features like copy and paste, drag and drop, and contextual menus allow users to adapt quickly to the tool. An intuitive interface reduces the learning curve and enables designers to work more efficiently.

2. Associativity for Reliability

Associativity is a feature that automates the updating of one element in relation to another. For example, moving a screw will automatically adjust the holes, and changing the length of a chassis will reposition the associated components. This feature reduces the risk of errors and saves time in the design process by ensuring that all related elements are updated simultaneously.

3. Versatile Design Methods

A good CAD software offers multiple design methods, including bottom-up, top-down, and in-place design. Bottom-up design involves creating individual parts first and then assembling them, similar to building with LEGO® bricks. Top-down design starts with the overall constraints and then deduces the necessary assemblies and parts. In-place design, a variation of top-down design, allows parts to be designed within their assembly context, simplifying the creation of connecting parts.

4. Enhanced Productivity and Quality

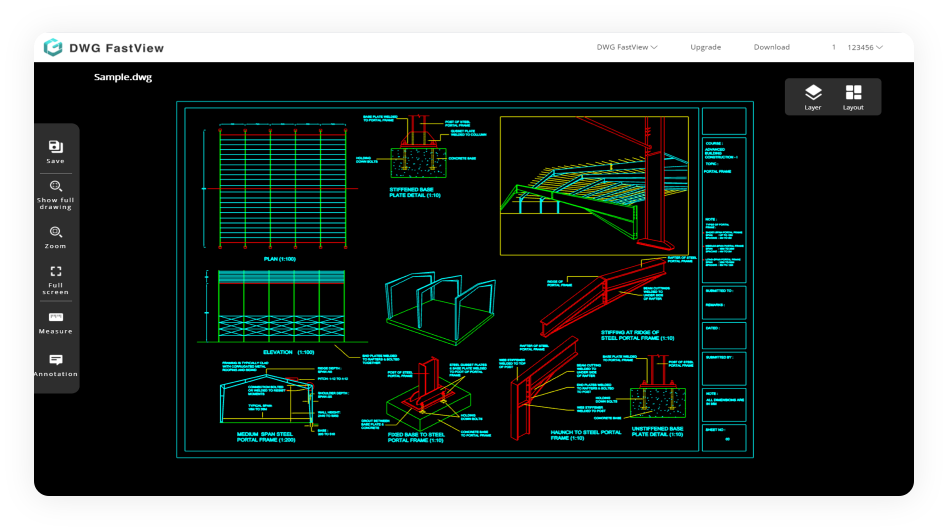

CAD software significantly improves productivity and design quality. It allows for easy modification, documentation, and collaboration of designs. Designers can create accurate 2D drawings and 3D models, visualize properties such as height, width, distance, color, and material, and build entire models for any application. This leads to fewer revisions and a more efficient workflow.

5. Applications Across Industries

CAD is used in a wide range of industries, including architecture, engineering, construction, product design, graphic design, and manufacturing. It helps in creating precise drawings and models, improving communication, and providing a database for manufacturing. CAD software also incorporates cloud technology, enabling remote access to projects and facilitating collaboration among team members.

6. Integration with CAM

CAD software often integrates with Computer-Aided Manufacturing (CAM) software, providing more control over the entire process from conceptualization to realization. This integration allows for seamless transition from design to manufacturing, ensuring that the final product meets the design specifications.

7. Simulation and Real-World Functionality

Modern CAD software includes features for simulating real-world functionality. Designers can test how their designs will perform under various conditions, identify potential issues, and make necessary adjustments before actual production. This reduces the risk of costly errors and enhances the overall quality of the final product.

Conclusion

The essential features of CAD software, such as a modern user interface, associativity, versatile design methods, enhanced productivity, and integration with CAM, make it a vital tool in today’s design and engineering landscape. By leveraging these features, designers and engineers can create high-quality, accurate, and efficient designs that meet the demands of various industries.