Modern Videoscope Capabilities for Easier Weld Inspection

Nondestructive examination plays an important role in equipment diagnosis during the maintenance of welded structures. However, inspection using ultrasonic flaw detection can be difficult or even impossible if the weld is inaccessible. The good news is that new remote visual inspection (RVI) technologies have been developed that enable highly efficient and accurate weld inspection. Testing methods are also diversifying.To get more news about video borescope, you can visit seesemborescopes.com official website.

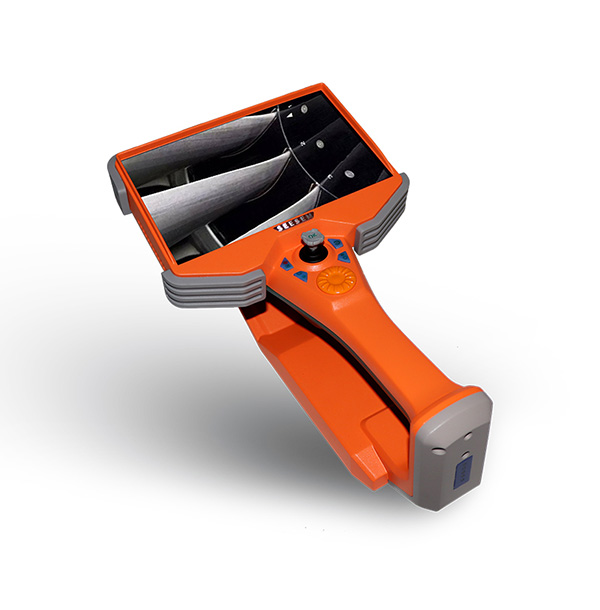

One RVI technology that offers more effective weld inspection is the modern industrial videoscope, an advanced type of borescope with video and still image recording capabilities. This article will review the videoscope’s capabilities for overcoming common weld inspection challenges.

The Challenges of Visual Inspection in Welding

The ISO standard for visual inspection of welds in metallic materials (ISO 17637:2016, Non-destructive testing of welds — Visual testing of fusion-welded joints) states that welds can be inspected directly if access is sufficient or remote using borescopes and other relevant RVI equipment.

An industrial videoscope can be inserted into pipes and tanks that cannot be accessed from the outside, giving inspectors a clear view of the welded parts inside. This visual inspection helps inspectors determine the need to repair or replace equipment for pipes and tanks.

Many modern videoscopes come with a measurement function that can quantitatively measure the length, height, depth, and sizes of defects. Even if it is hard to judge the need for repair from the image of the weld, the measurement function can aid in the visual inspection. This function also eliminates the need for extra equipment like gauges to take measurements.

Conventional 2D images have generally been used for videoscope measurements of cracks, heat effects, and corrosion on welded parts. Yet, these 2D images present a challenge: It is hard to visually determine depth on a flat image. Since the inspector must place the measurement points manually, it takes time to confirm the measurement and can lead to reduced confidence in the results.

Simply put, 3D modeling is a videoscope feature that helps inspectors easily understand the shape of complex components through various 3D displays of the target object. For example, you can rotate the 3D model of the target to check the positions of the measurement and reference points, remove unnecessary objects from the cross-section display, and color code the protrusions and dents to see them at a glance (Figure 2).